| 1972 | Single Wound Heating Wires |

| 1982 | Dual Wound Heating with Fusible Layer for "Overheat Protection" |

| 1990 | Negative Temperature Coefficient "Heat Sensing" for Temperature Monitoring and resettable hot spot detection |

| 1992 | Positive Temperature Coefficient for accurate overall Temperature Monitoring |

| 1996 | NTC and PTC - twin temperature monitoring in one wire |

| 2002 | "Total Control Technology" - the first heating wire to have five levels of safety |

| 2003 | Low EMF solution. Electro-Magnetic Radiation reduced to 50 nanoteslas |

| 2004 | Patent protection applied for a low EMF wire solution |

| 2005 | Patent protection applied for a control solution for low EMF wire and other Thermocable products |

| Today | Thermocable continues to work closely and co-operate with many of the world's Leading Manufacturers of

Electric Blankets and Heating Pads to improve the Safety, Reliability and Functionality of Flexible Heating Products |

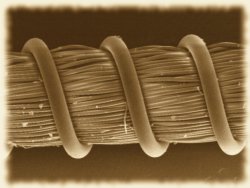

Positive Temperature Coefficient wire. As the temperature of the element wire increases the resistance increases.

Positive Temperature Coefficient wire. As the temperature of the element wire increases the resistance increases.

Negative Temperature Coefficient separation layer. As the temperature of the layer increases, the resistance

decreases.

Negative Temperature Coefficient separation layer. As the temperature of the layer increases, the resistance

decreases.